Lifting Station Manholes

Made from HDPE in diameters up to DN/ID 3000 mm

KRAH Manholes

for Lifting Station

Thermoplastic Manholes and Chambers have been successfully used for the municipal or private sewer or storm water networks decades around the globe, and as well as in the Sultanate of Oman. KRAH, located in Rusayl Industrial Estate was established in the year 2009 in Dubai with a vision of becoming one of the solution providers and the market leader in GCC by producing and supply of thermoplastic pipes and other associated products using KRAH Technology. Excellent material properties of the HDPE to handle aggressive liquids like sewage waste, acids and gases that are released has prompted the concept of the manhole to be used as a Wet Well lifting station for the sewerage network.

Presently KEPM manufactures the shafts or cylinders for the tank up to DN/ID 3000 mm and a length of 6000 mm. The shafts can be produced either is Solid wall or Structured wall with special sections to increase the stiffness to withstand the radial load and axial loads. Being robust in design and light in weight, easy

handling, makes the installation possible in very short time. A smart solution for all kinds of savings during the installation and thus reduction of project

time.

General Design

Manholes or Chambers are tailormade for the network. The shafts for the manholes or chambers are designed to withstand hydrostatic pressure due to ground water, and the radial loads due to soil and live loads considering and other conditions. The static design of the vertical shafts is mainly according to the international accepted standards ASTM F1759 and ATV 127. To facilitate the calculation, KEPM uses a special software program “Easy Schacht”, where all conditions like ground water, traffic loads are considered to calculate the optimum structure. The wall thickness is designed to according to the static requirements and due to the helical extrusion technology of KRAH, the wall is completely monolithic and homogeneous.

Production Technology

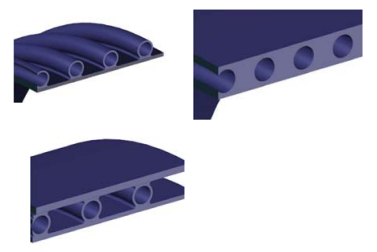

UGPM uses KRAH Technology to manufacture large diameter cylindrical shafts with the helical extrusion technology, which gives a reliable, safe solution with high quality in its construction.

The combination of the transverse movement of the extrusion head along with the rotational movement of the mould forms the helical winding of the molten material. The material being molten the jointing between the layers while forming the helix is

homogeneous. The manufacturing method involve the helical extrusion on a mould or mandrel, thereby a seamless cylindrical shaft is produced, no frozen stress in the wall.

The bottom base plate is also produced using the same technology from PE 100 material. The various components are then assembled and joined together by extrusion welding.

The materials used to manufacture is HDPE with excellent corrosion resistant properties, being chemically inert to most products.

The KRAH Production Technology at a Glance:

- Stepped wall thickness or varying wall thickness in a shell can be produced according to hydrostatic load.

- Lightweight profile sections facilitate obtaining high inertia suitable for use in vacuum tested equipment or in horizontal and buried tanks.

- The technology allows the construction of double- walled cylindrical shells which are fully monolithic (a single part)

- The shells can be produced with inner layer of different colors to improve visibility inside or to add an internal or external cladding with electro conductive material.

- The bases are manufactured from plates of the same material as the cylindrical shells.

Advantages

- Light Weight and easy handling

- Excellent Abrasion Resistance

- Weldability

- Good Chemical Resistance

- Resistance to microorganisms, rodents and termites

- UV Resistance

- Impact Resistance

- Deformation Resistance

- Installation o Easier and quicker handling. o No risk of brittle breaks. o No risk of structural collapse due to unforeseen loads. o Additional fittings/materials are not required for the connections. o Water tight homogeneous network.

- Eco-friendly – 100% recyclable

- Easy modification at sites

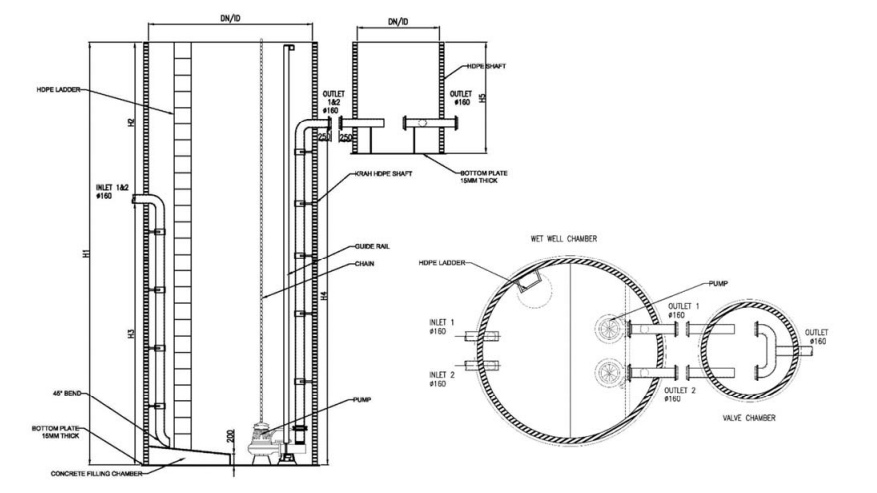

KRAH Lifting Stations (Wet well) are supplied with:

- Piping along with the support brackets.

- Antifloatation fins or base, in case of water table area

- Ladders

- Special attachments

- Guide rail fixture (guide rail

- to be provided)

- Valve Chamber with piping and fittings for connection

- Pump support (pumps to be provided)

Availability

Lifting Station Manhole

- Application – Wet well

- DN/ID DN1200, DN1500, DN1800, DN2000, DN2400, DN3000

- Depth up to 6 m. Higher depths on request

- Available for ground water conditions and no ground water conditions

- Traffic loads

- Standard 3 or 5 inlet thermoformed benching.

- Fabricated benching with special orientation.

Valve Chamber

- Application

- Valve – DN1000, DN1200, DN1500, DN1800, DN2000, DN2400, DN3000

- Depth 1 – 4 m. Higher depths on request

- Available for ground water conditions and no ground water conditions

- Traffic loads – Piping with fittings

- Valves and NRV to be provided

When

Monday-Friday

07:30 – 16:00

How

+971 2 6423 999

+971 50 555 7777

Where

MQ Tower, 543 Muroor Road, Abu Dhabi, UAE