Jointing Technologies

All Krah pipes are produced automatically with a socket and spigot, which are adaptable to the following kinds of jointing techniques

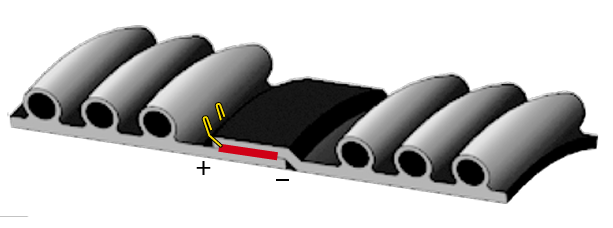

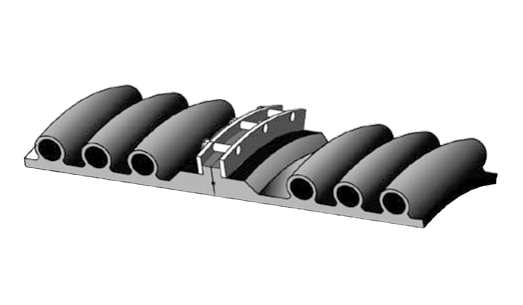

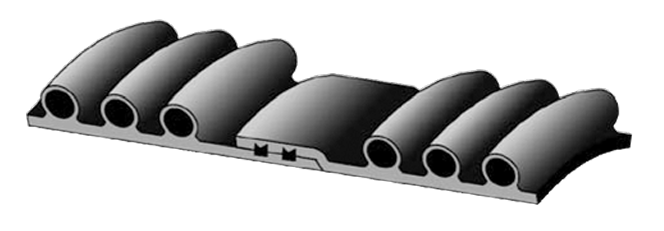

Electrofusion Joints

This is the most preferred joint system, as the whole pipe system becomes a homogenous unit.

A welding wire which is included in the socket or spigot is heated with the help of a special welding device whereby the two pipe ends (the socket and the spigot) are jointed together. The electro fusion jointing technique is a very favourable, simple and secure method to install pipes in even very narrow trenches in a short time. For further information please refer to our brochure «Technology – integrated electro fusion joint».

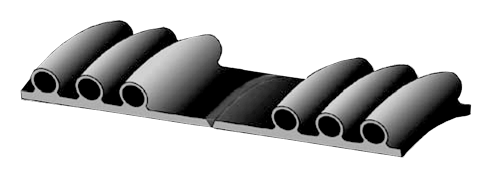

V Stream Extrusion Welding

Extrusion Welding

The pipes and/or fittings which shall be connected are jointed by a socket and spigot joint. Thus the two pipe ends are connected with the help of an extrusion welding device. The jointing method can be carried out inside or/and outside of the pipe.

This jointing is most suitable for low-pressure gravity pipes and manholes.

The welding has to be done according to DVS

2207 part 4

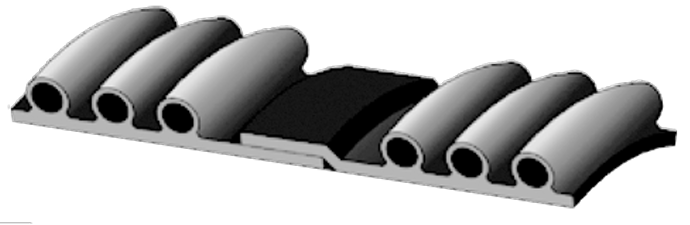

Heat Element Butt Fusion

The pipes and fittings are jointed with the help of a heating element butt welding machine. The ends of the pipes and fittings are butt-welded. This kind of jointing method is only recommended for pipes and fittings with a maximum wall thickness of 150 mm and with diameters from DN/ID 300 mm to DN/ ID 2500 mm.

The welding has to be done according to DVS 2207 part 1.

Flange Connection

The ends of the pipes and fittings are jointed with the help of a steel flange and a rubber gasket. Depending on the type of pipe the flange adapters are completely manufactured with the pipe, or the flanges are available as separate fitting. This kind of jointing method is mostly used for open sea discharge application and for tank connections. The greatest advantage of this connection is the facility of disjointing.

Gasket Connection

The ends of the pipes and fittings are jointed with the help of a steel flange and a rubber gasket. Depending on the type of pipe the flange adapters are completely manufactured with the pipe, or the flanges are available as separate fitting. This kind of jointing method is mostly used for open sea discharge application and for tank connections. The greatest advantage of this connection is the facility of disjointing.