KRAH PIPES

Polyethylene Pipe System for Infrastructure

Most sewage and waste water systems in Middle East and Asia are still designed in conventional materials such as concrete, clay and asbestos cement. However, with the introduction of thermoplastics like HDPE, a versatile material, there are many benefits offered, which needs to considered for building a sustainable infrastructure. KRAH Emirates Pipes Manufacturing Co. LLC, located in Musaffah South ICAD II, U.A.E was established to manufacturer various products suitable for the modern and the sustainable infrastructure for applications like sewerage, storm water, etc.

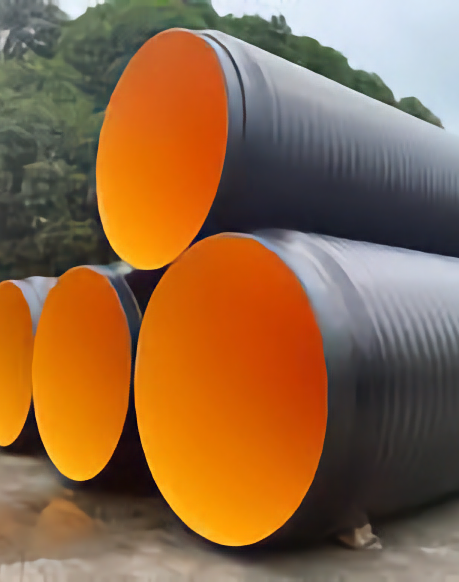

With its expertise in the large diameter pipes using a unique technology from Germany to be produced in the UAE and to market as “Made in UAE” product to the domestic and in GCC region. KRAH Emirates Pipes Manufacturing Co. LLC is the sole owner of the technology to produce the large diameter pipes for infrastructure and other associated products to build a sustainable and resilient infrastructure as shown.

HANDLING & TRANSPORTATION

Pipes and fittings have to be transported with appropriate vehicles. During the transport and especially during the loading and unloading they have to be protected against damages. During the unloading the pipes using hoists, only belts, that is safe to handle, should be used. Steel wire ropes, chains as wells as sharp-edged lifting devices should be avoided. While unloading of the pipes with a fork-lift, the forks that carry the pipes should be examined for any sharp edges. It is recommended to wrap the forks with a protecting foil or to use a suitable pipe inside the pipes that have to be unloaded. The pipes should be stored on even ground which is free of stones or sharp-edged objects. The pipes are to be stored in such a way that they cannot deform and are protected against dirt, mechanical damages, and pointed load and this applies especially for the spigot and the socket that is integrated with the electrofusion wires. HDPE Manholes are usually equipped with lifting lugs that welded homogeneously to ensure safe loading and unloading on the site as shown in the picture. All these lugs are homogenously welded to the pipe.

JOINTING

- Electro fusion joint

- V seam extrusion welding

- Extrusion welding

- Heat element butt fusion

- Flange connection

- Gasket connection

Installation & Testing

KRAH pipelines are engineered products. The basic installation for these pipes is based on the worksheet ATV A 127. The basis of the installation procedure is:

The embedding of the pipes considerably rules the load distribution and the pressure distribution on the pipe to prevent from any deformation. It is always recommended to use a compactor to compact the soil to the desired level. All materials which are defined in the EN 1610 can be used for embedding the pipes, materials like washed gravel, crashed gravel, sand, granular ground. The mechanical compaction of the main backfilling directly above the pipe should only be started when a layer of minimum 300 mm is above the apex of the pipe.

Note: The compaction which is determined in the static calculation cannot be reached with wet compaction material with less than 11% of humidity

STANDARD

- Gravity Pipes – EN 13476, DIN 16961 Statistical dimensions

- ATV A127 Hydraulic dimensioning

- ATV A 110 Pipe Installation

- EN 1610, ATV 139 Jointing of the pipes

- DVS 2207 Vertical shafts for manholes

- BS EN 13598, ASTM F1759 & ATV 127

Availability